What is First Surface and Second Surface Printing?

Second Surface Printing

Second Surface printing adds a layer of elegance to any display by printing on the back, rear facing side of the material. The benefits of second surface printing vary by substrate, but here are a few examples of how this printing method is useful for all industries:

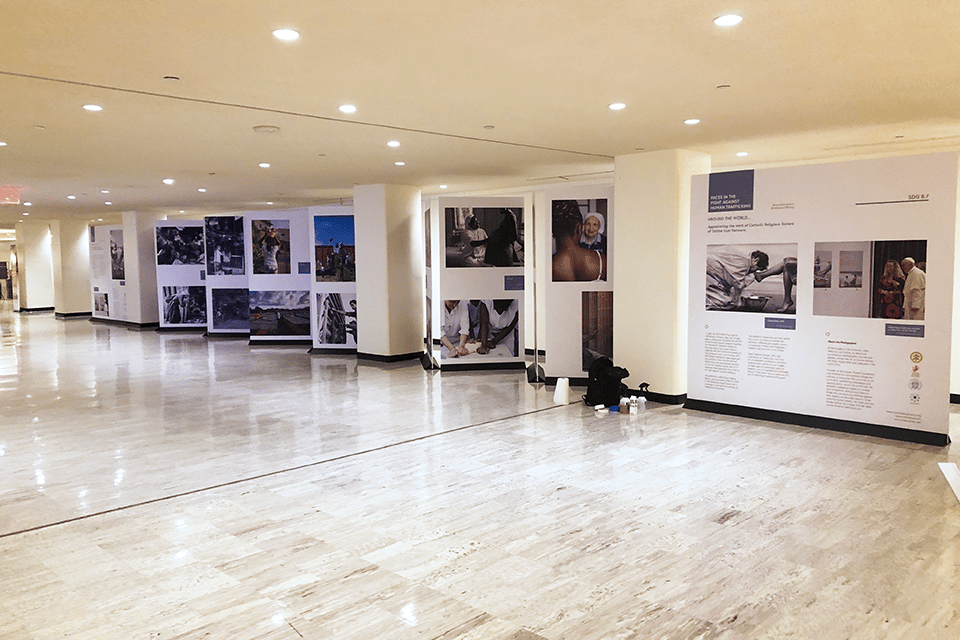

- Second Surface Printing on vinyl allows for signs to be displays from the inside of a window – protecting the print from weather conditions.

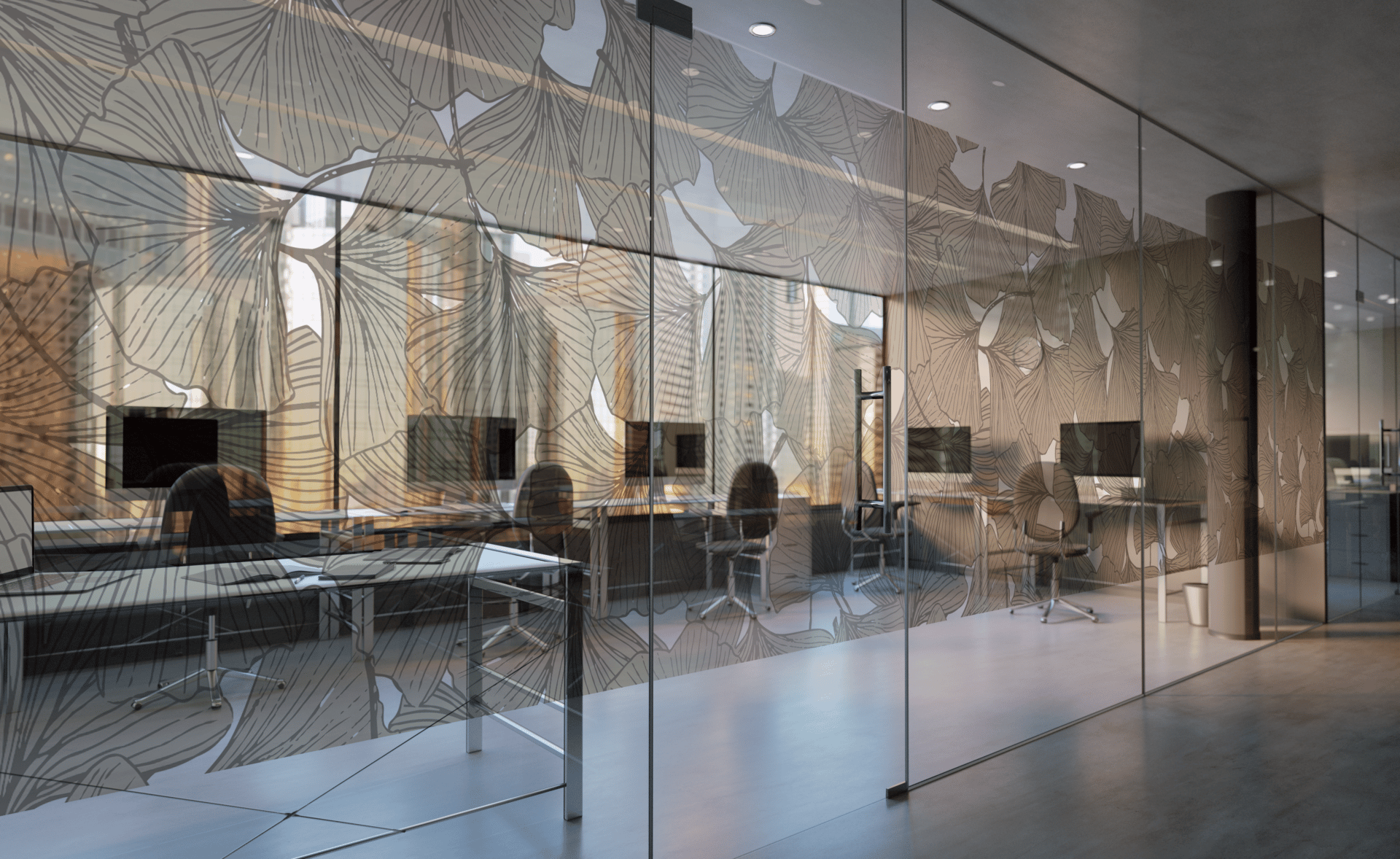

- When using film, the print can be taped, hung, or suspended with clamps on the inside of the window. Printing on the back of the material gives the sign a more finished, modern look vs. traditional first surface printing.

- On Acrylic, second surface printing eliminates the need for framing as it gives an already framed look to the sign. By printing on the back of the clear acrylic, the sign is given more depth and has a high-end display.

First Surface Printing

Printing on the first surface of acrylic, vinyl, or film is how displays are traditionally created. Ink is applied to the front, customer-facing surface of the piece through a flatbed printer. This type of printing can be done on nontransparent, colored material for added vibrancy, and can also be printed on transparent for more subtle displays. First surface printing brings a timeless display to any printed piece, and special effects like white ink can add even more customization opportunities.

Interested in using First or Second Surface print on your next project? Request a Quote today!